The restoration process

Artigiani del Restauro is a mechanical workshop that can offer a complete restoration and repairing service for Berkel fly-wheel slicers, thanks to a combination of particular handicraft care and industrial technologies.

The company buys and retrieves the antique Berker slicers with the aim of restoring and taking them back to their original splendor and perfect functionality, carrying on the entire restoration process inside its plant in Oggiona S. Stefano (VA). The entire process developed to transform some “old” used Berkel slicers into perfectly working, full fledged masterpieces, is what makes Artigiani del Restauro unique in the Berkel restoration world. The restored slicers can be used as design furnishing component in private homes or as highly valuable and well performing tools in restaurants and hotels. In order to offer our customers a complete service with a product restored to new, Artigiani del Restauro care with thoroughness every single phase in restoration process of the Berkel slicers, without being neglectful on any detail.

Furthermore, during all the Berkel restauration phases the company employs the use of high quality products, complying with the highest safety standards : on painting exclusively water base products are used, making all machines suitable for contact with food; the screws and iron, aluminum or iron-cast parts are submitted to polishing, copper-plating, nickel-plating and whether demanded chrome-plating as well.

The expertise and accuracy in the mechanics distinguishing the Artigiani del Restauro, allow the company to get the old used Berkel slicers to perfectly work again.

The Berkel slicers restoration phases

#1 DISASSEMBLY

The Berkel slicer to be renovated gets totally disassembled with the greatest care. Every single piece gets removed and carefully checked. Whenever some parts result damaged or unusable, new slicer Berkel parts will be rebuilt.

#2 WASHING

Every single piece of the Berkel slicers to be restored is submitted to accurate washing by means of appropriate machines to take any residual materials off their surface. This is the first step of the process needed to take the parts back to their original status.

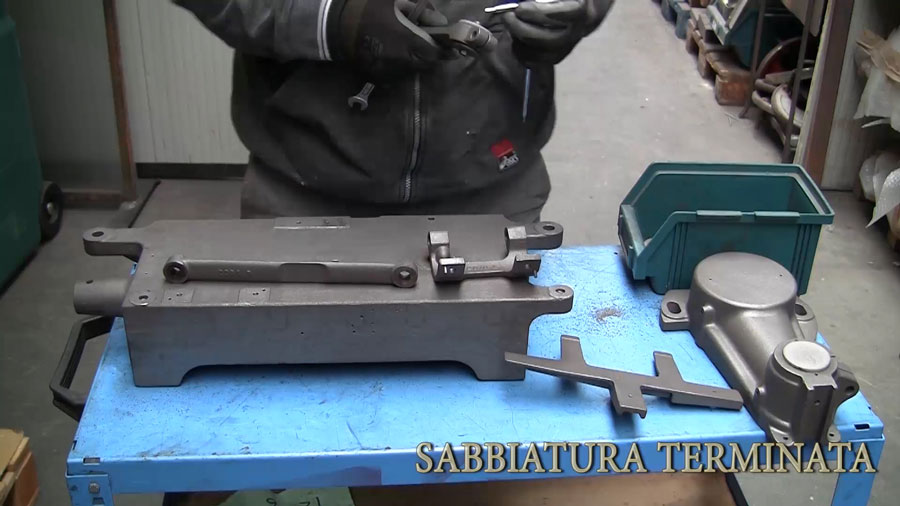

#3 SANDBLASTING

The following step is the sandblasting of the Berkel slicer parts which are to be successively painted. Through it, the upper surface ply of the piece will be eroded, thus cleaning it off any paint left-overs, calcifications, oxide, or other coatings.

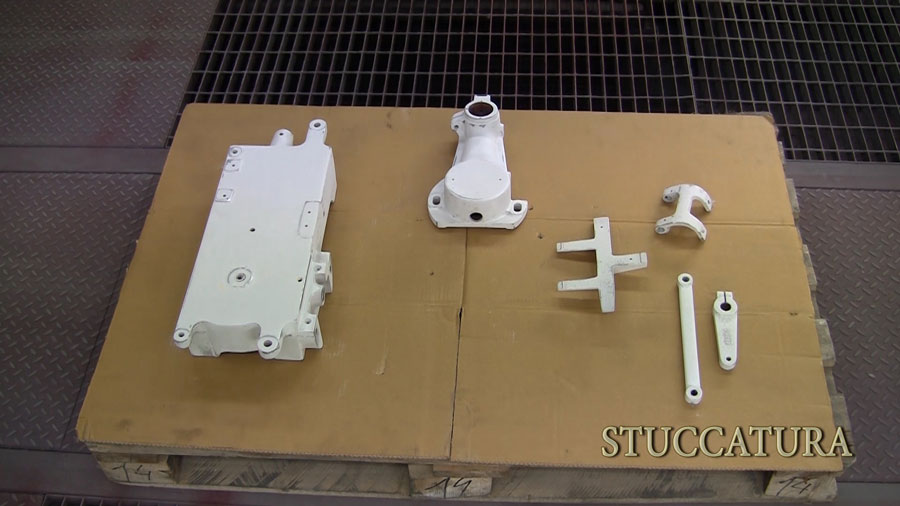

#4 PLASTERING

To prepare them to their successive treatment to primers and paints, the sanding and plastering of the berkel machines parts are manually executed.

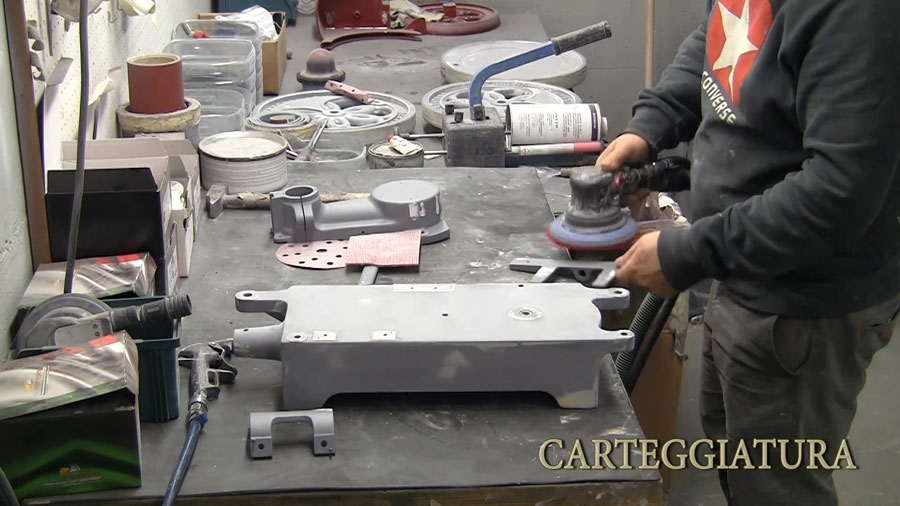

#5 PAINTING

The primer and paints get prepared. A first coat of priming is given, so to shift then to the true and proper painting of the Berkel slicer to be restored. After that 11 layers coating are applied: primer, color lacquer, hand or airbrush decoration and transparent shining finishing.

#6 DECORATION

It goes then with the decoration the Berkel Slicer, fulfilled manually through some aerographs. Decorations are made manually.

#7 POLISHING

3 layers of transparent coating on all lacquered parts and an accurate hand polishing of the machine will get the restored Berkel slicer back to its original charm and beauty.

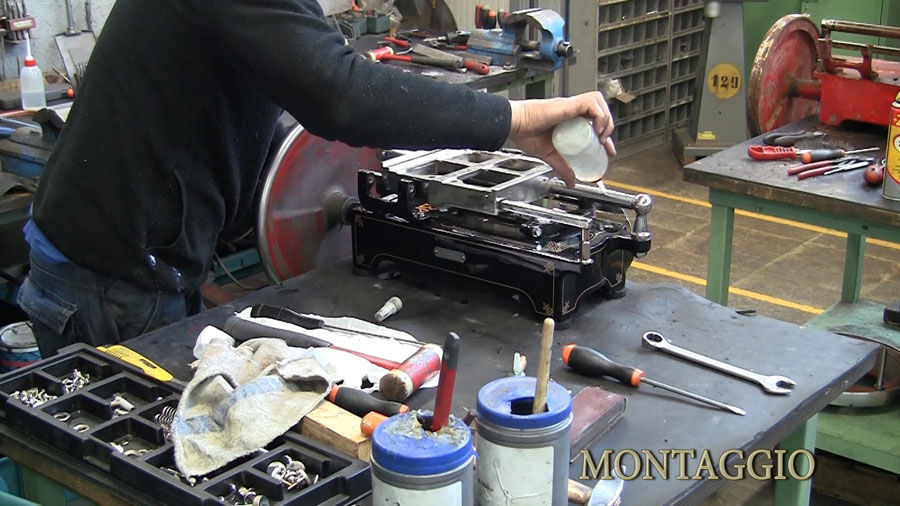

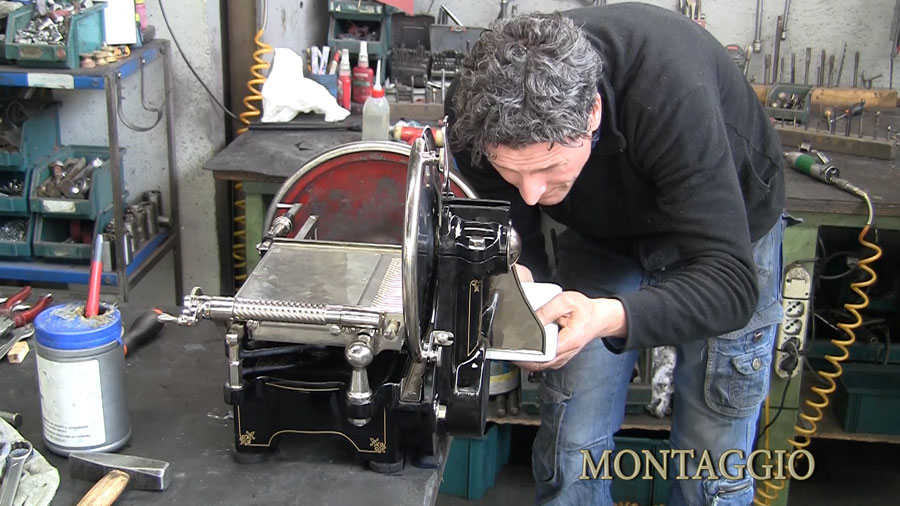

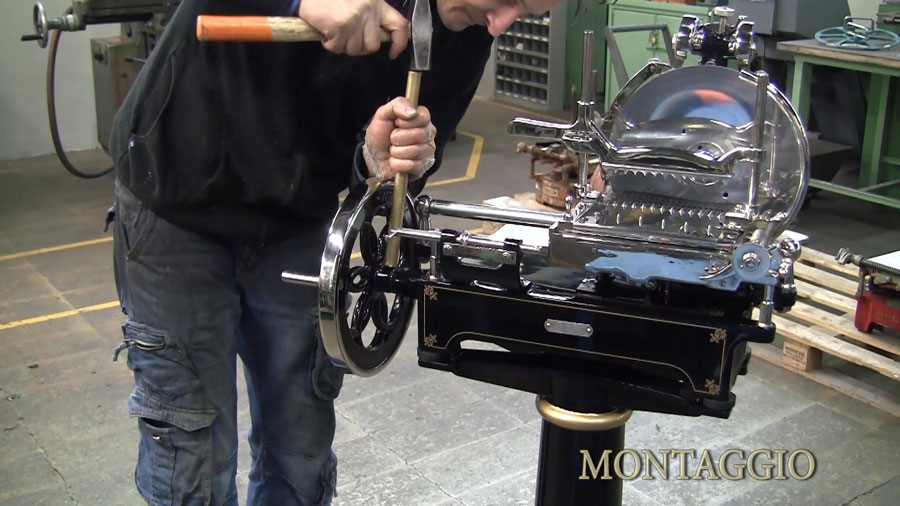

#8 ASSEMBLY

All mechanical parts, painted parts and screws are put together on the Berkel slicer. At the end blade, stones, tray and ribbed plate are assembled: the renovated Berkel slicer is ready to work, brand new looking and forever lasting.

Do you have a Berkel slicer to restore?

Are you interested in buying one already restored and would like to discover the prices of the ancient Berkel slicers we offer?

Contact us for more information on our services.