MODEL:

PRODUCTION:

1936 – 1969

COLOR:

Black / Cream / Red

TECHNICAL DATA:

HISTORICAL NOTES

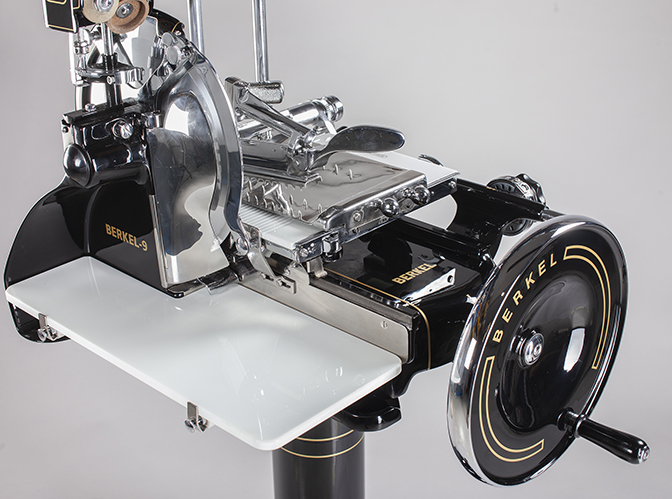

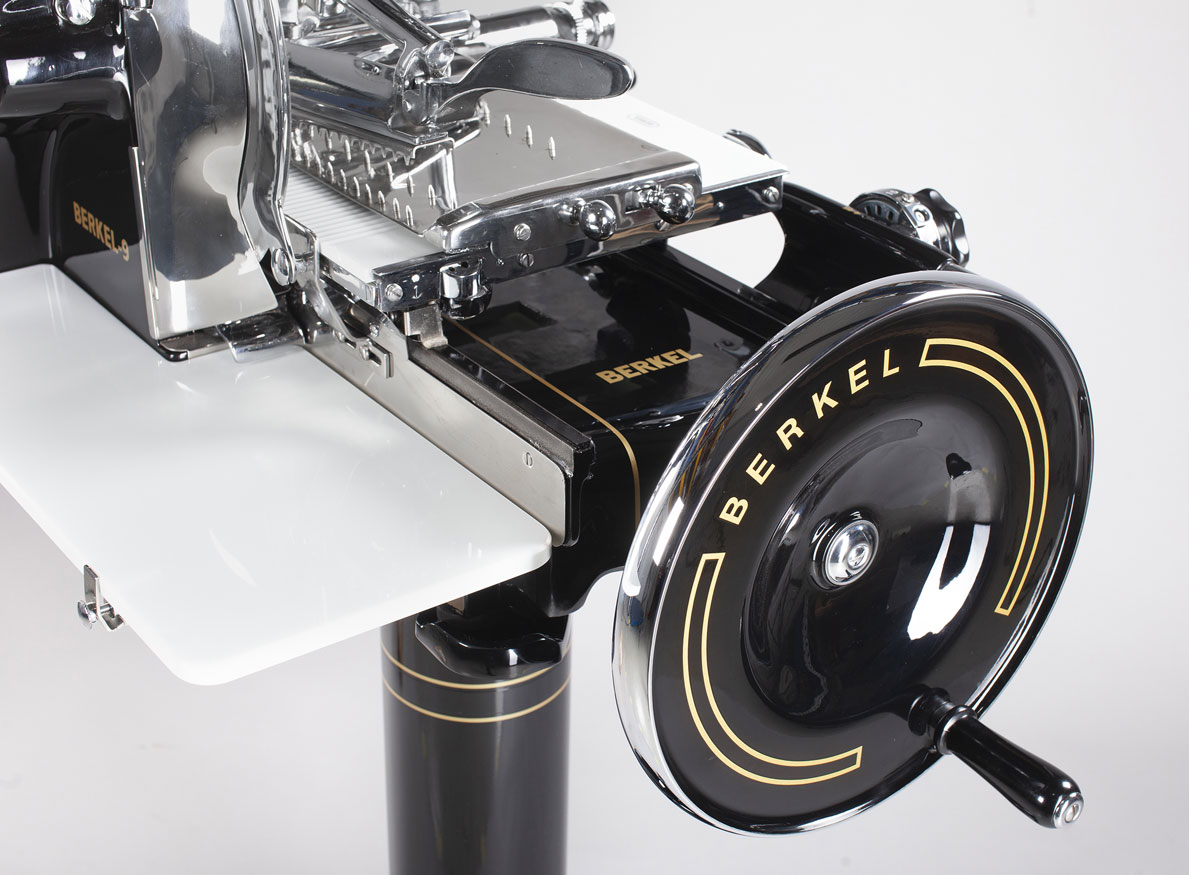

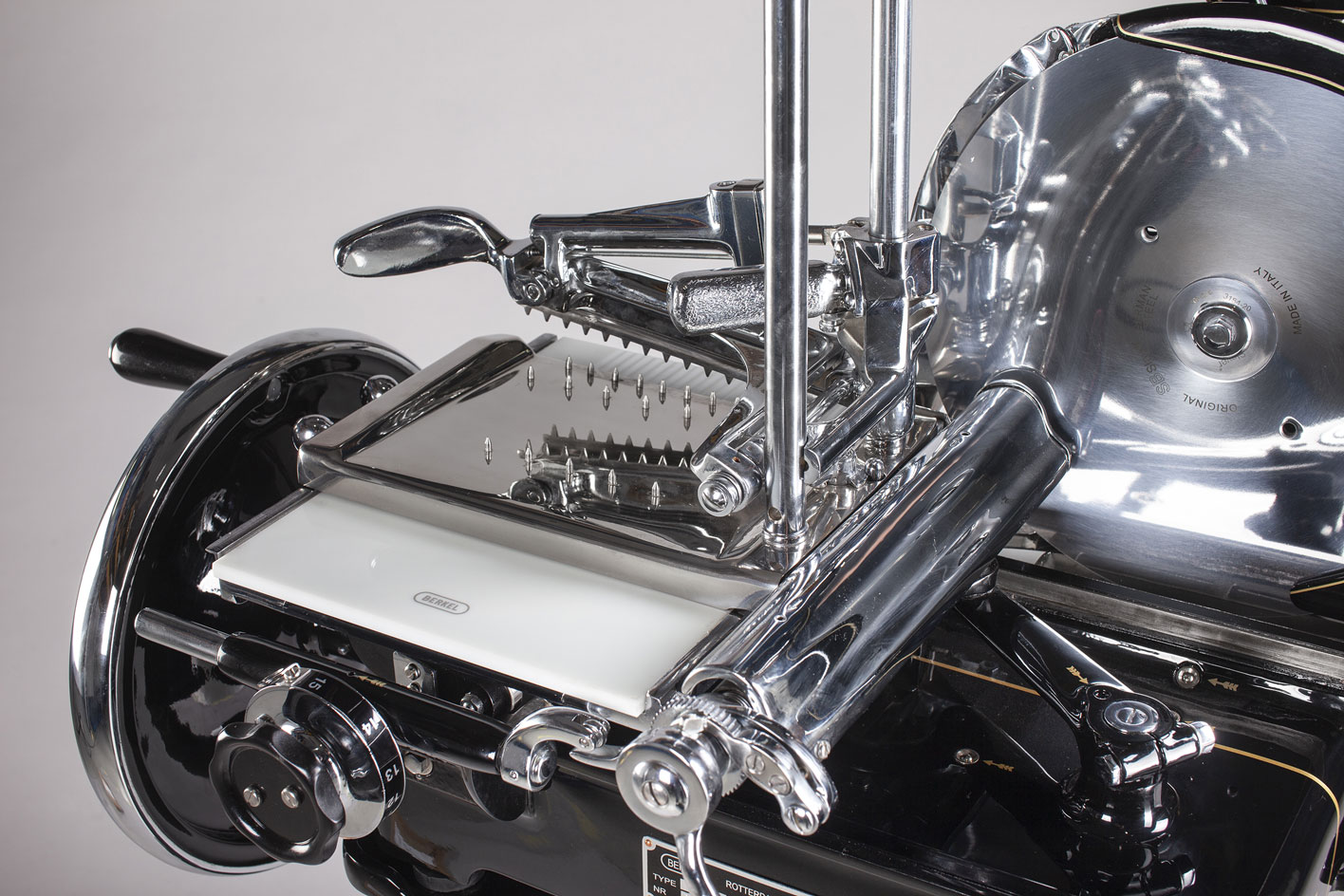

The model 9H Berkel slicer had been produced since 1936 and distributed ’till 1969. It’s about a flywheel slicer with contained dimensions which shows mechanical aspects and slicing efficiency equal to the most sophisticated models. In fact, in all the Berkel 9H series, the slicing synchronism is similar to versions 5 and 7. Yet, the components were improved and optimized at the point that Berkel decided to use them ‘till the 60s during all the successive production. With Berkel Model 9H manual slicer we shift from the worm screw with ribbed clamp comb to the conical screw.

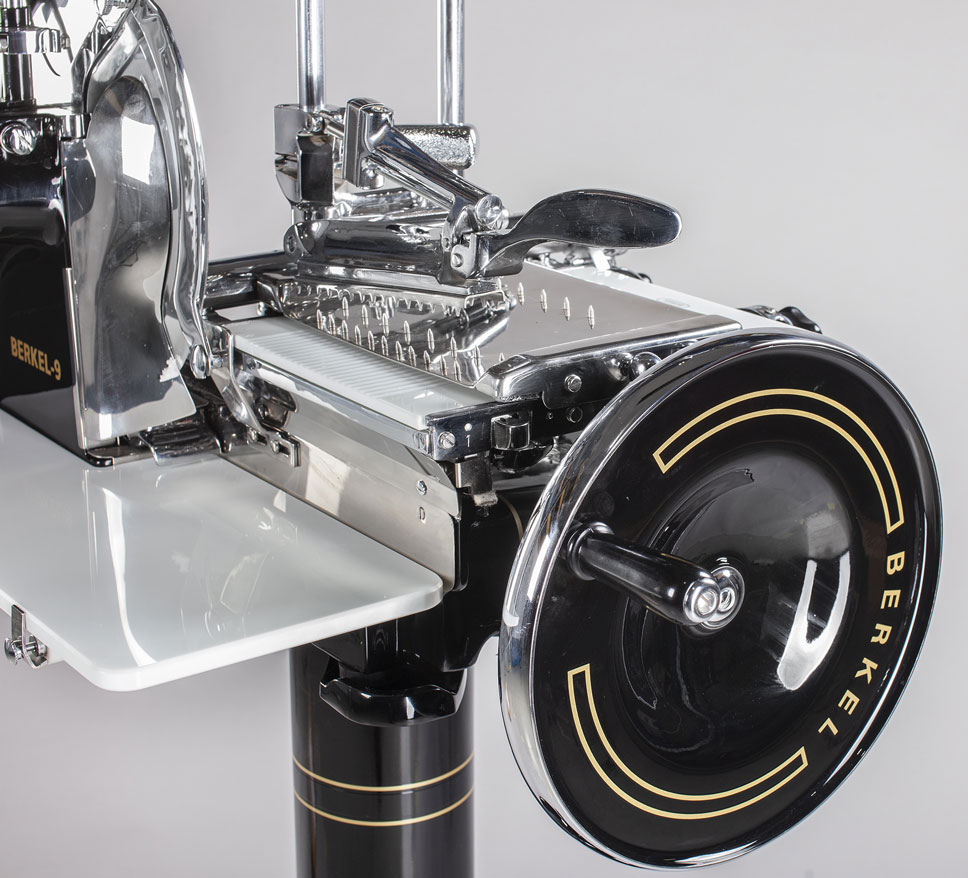

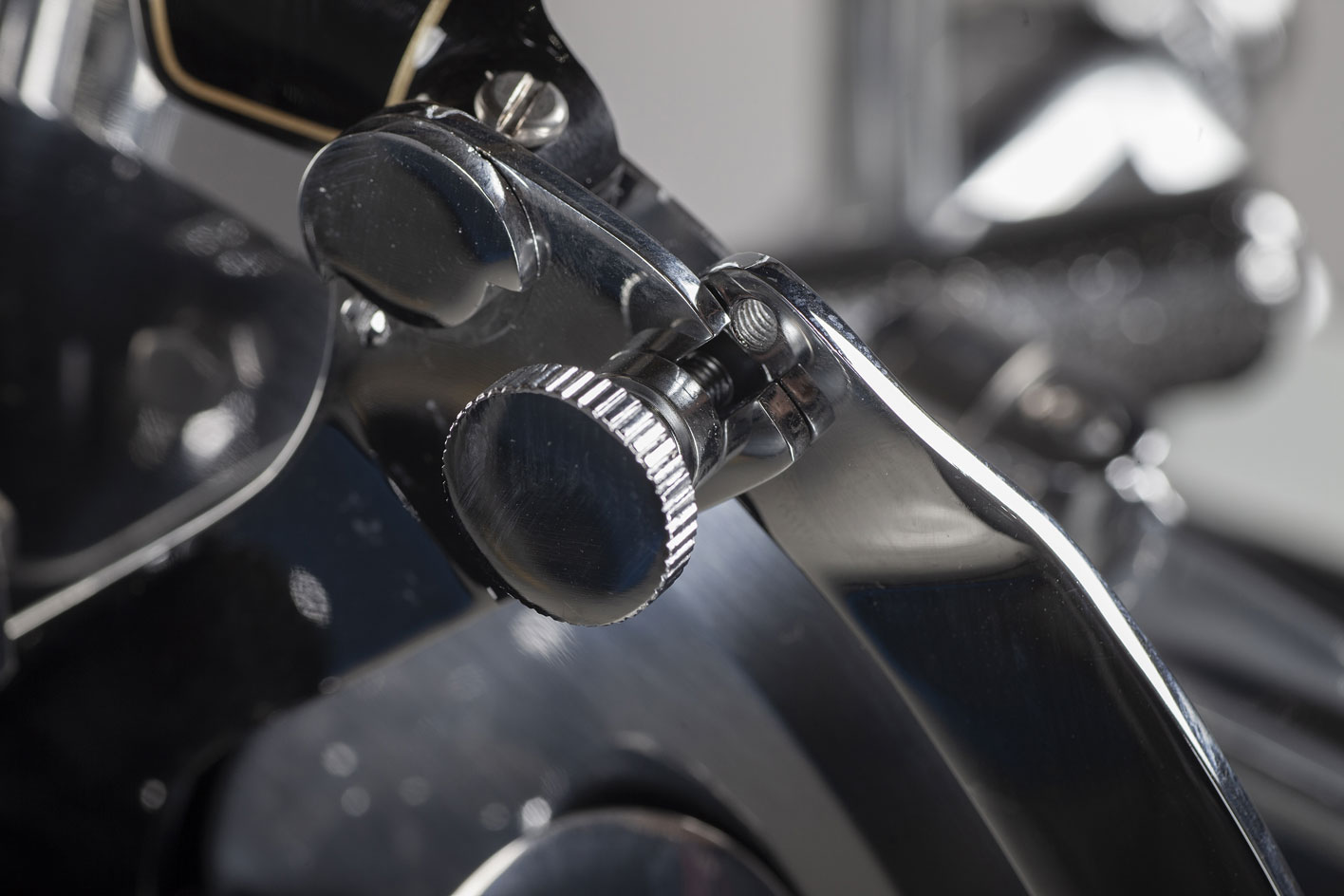

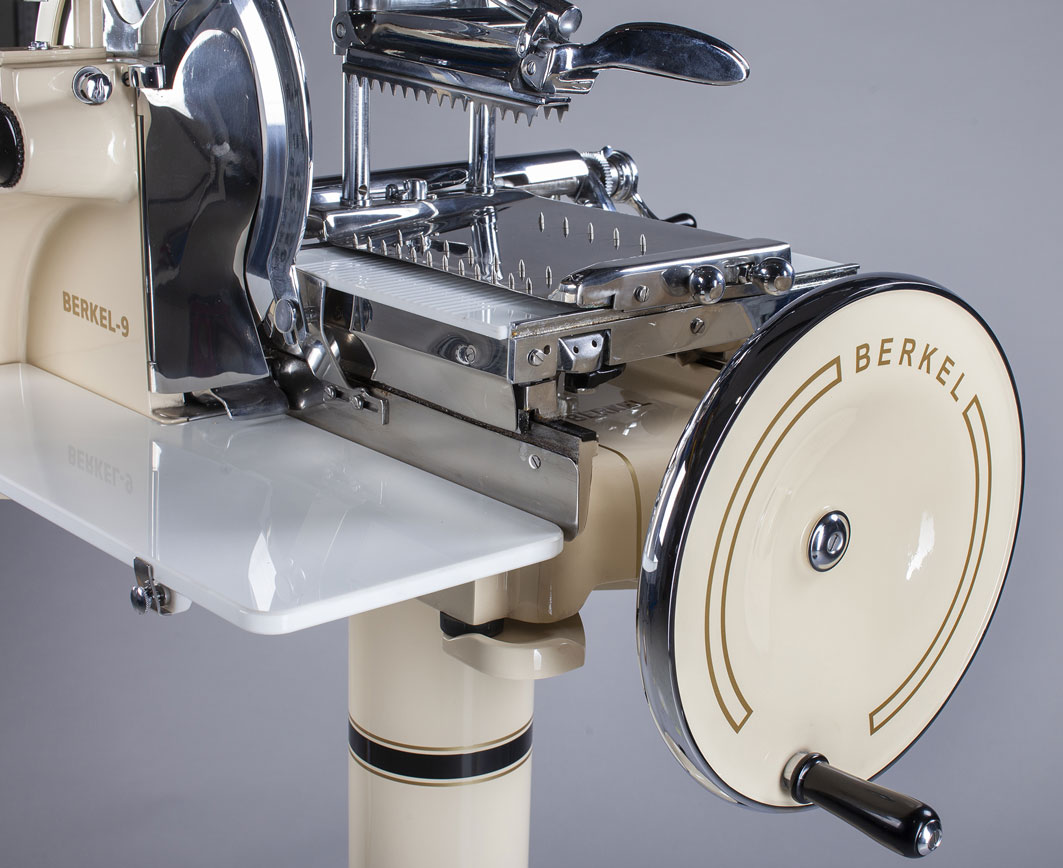

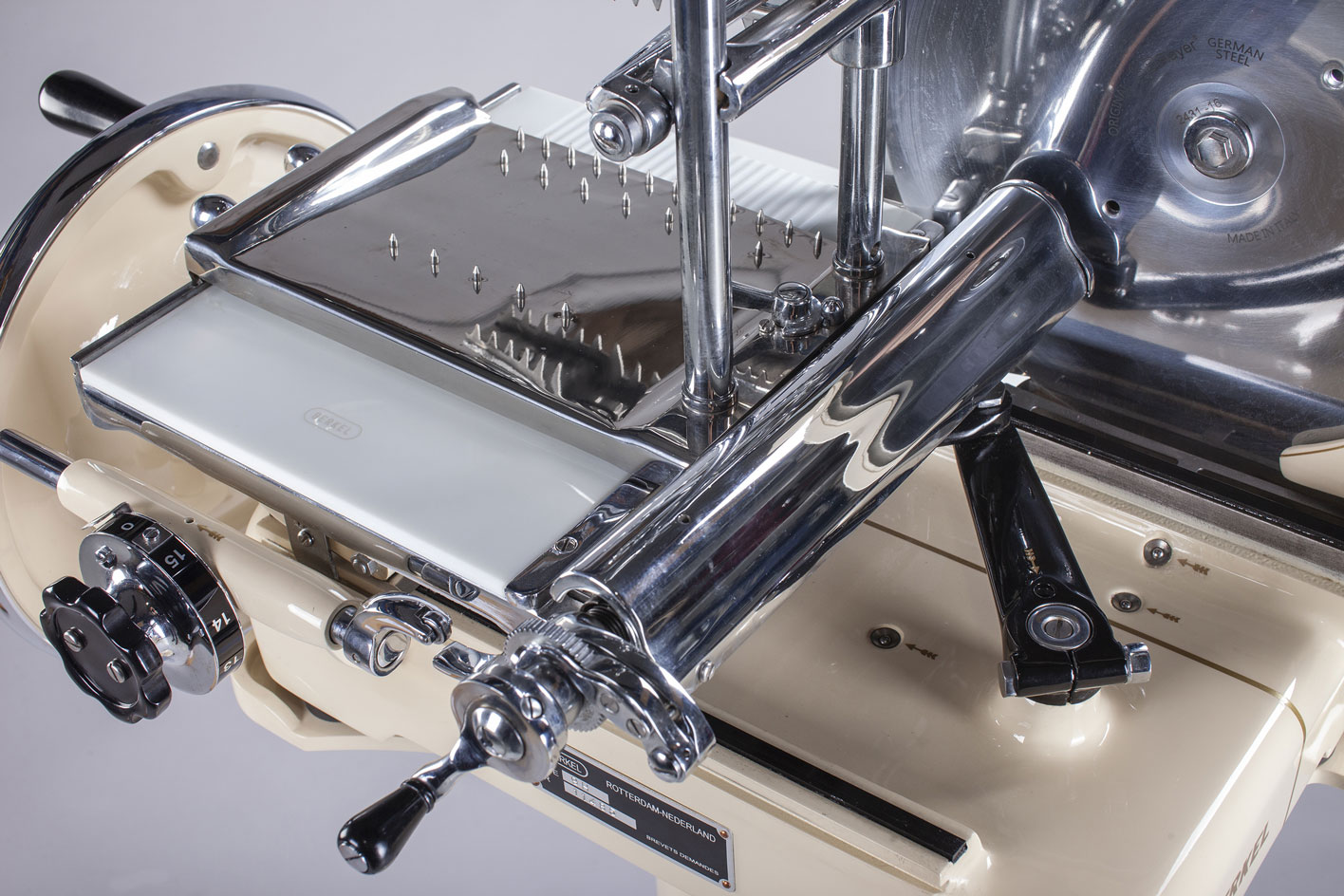

In addition to this, with Berkel Model 9H with Pedestal the machine comb doubles the contact surface and it’s no longer assembled onto the fixing clamp, but on a telescope scrolling headframe. Also, the comb is even inserted in the worm screw at a very high coupling charge. Such special device in Model Berkel 9H, together with the conical coupling, compensates the comb wear and allows to obtain the best efficiency and life length of such professional slicer. Upon the headframe a pin pokes out where the clamp is inserted and blocked in. The worm screw and the headframe in this design slicer are covered with a shaped carter, unlike the previous models in which they were immediately visible. It’s about a closed and smooth flywheel slicer.

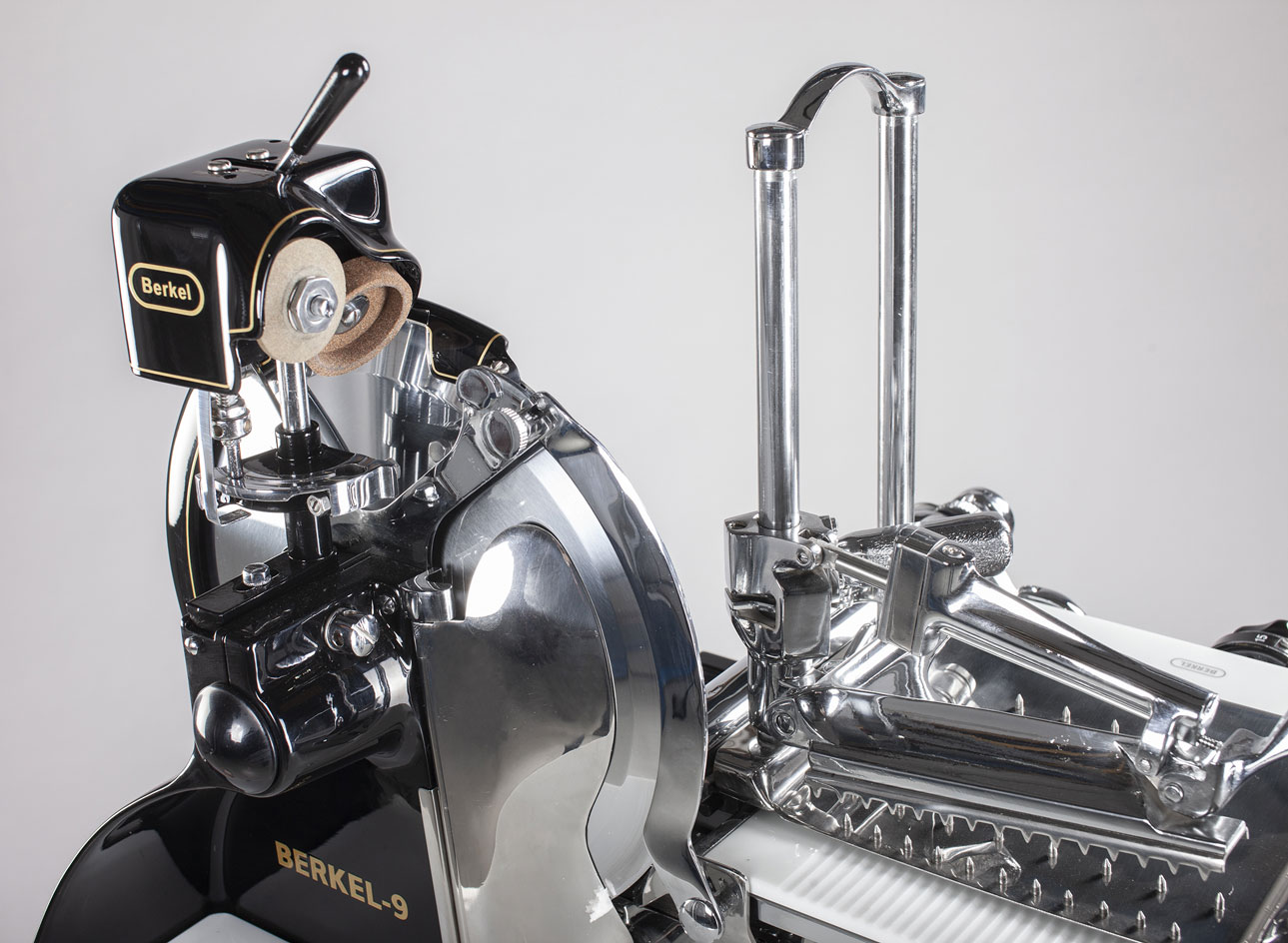

The fly-wheel operates the gears assembly placed at the machine base. Such gears generate in turn both the movement of its 319mm diameter blade – by means of a chain – and the scroll carriage – through two connecting rods. The scroll carriage of this professional machine moves upon guided wheels on a binary present on the base of the same machine. Here its fixed also for the slice thickness regulation, which will cause a peck-shaped lever in axle to the toothed wheel on the scroll carriage to be operated. The wheel in turn will convey the movement to the worm screw where the comb telescope headframe is. This in turn is hooked to the clamp thus generating the slicing movement . In this manual slicer, the toothed wheel is linked to a lever , which once operated, will move the clamp right or left according to the desired position.

The machine shoulder where the hub supporting the blade lies into, is flattened on its external side performing a wing-shaped bow. This will allow the extension of the machine tray so to have more working space on using the fly-wheel slicer.

It’s a flywheel slicer with a closed sharpener, covered by a painted crown. A lever will act on the cam causing the two stones for sharpening to move.

STANDINGS FOR MODEL 9H

Want to buy this Berkel Slicer?

Request information.

Restoration Berkel Model 9H

Artigiani del Restauro offer to all the owners of this machine a complete restoration service for Berkel model 9H. The company will fulfill the restoration cycle, by directly realizing – when needed or damaged – all the relevant parts of the machine. With a direct production of these components, by means of advanced technologies, Artigiani del Restauro may provide third party with the spares for Berkel model 9H. Also the company may sell already restored slicers of model Berkel 9H. The following colors are available : flywheel slicer Berkel model 9H red, flywheel slicer Berkel model 9H black, flywheel slicer Berkel model 9H cream. Contact us for further information or for an estimate on Flywheel slicer Model 9H.